About QDOS

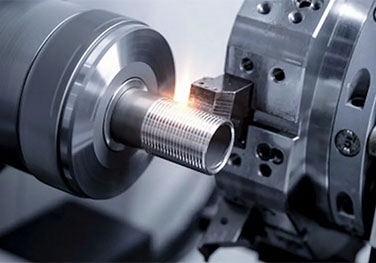

Qingdao OS Machinery Co., LTD., founded in 2014, is an enterprise integrating precision casting and precision machining. Engaged in OEM/ODM stainless steel/carbon steel/alloy steel machinery parts production and processing, annual output of 600 tons. Precision casting using silica sol process, product surface up to Ra6.3, size up to +/-0.10mm; Product processing, the company has four axis and horizontal processing equipment, processing accuracy of +/-0.015mm, can be four axis processing. Linkage and other complex products processing.

Made in China

Made in China

-1024x1024_376x263.jpg)